To solve shielding problems efficiently and cost-effective, SEKELS GmbH offers a long-term experience with theoretical and practical approaches. We measure and analyze interfering fields on site or in our lab, define the ideal design and alloy and produce from prototypes to series deliveries, of course including the necessary magnetic annealing.

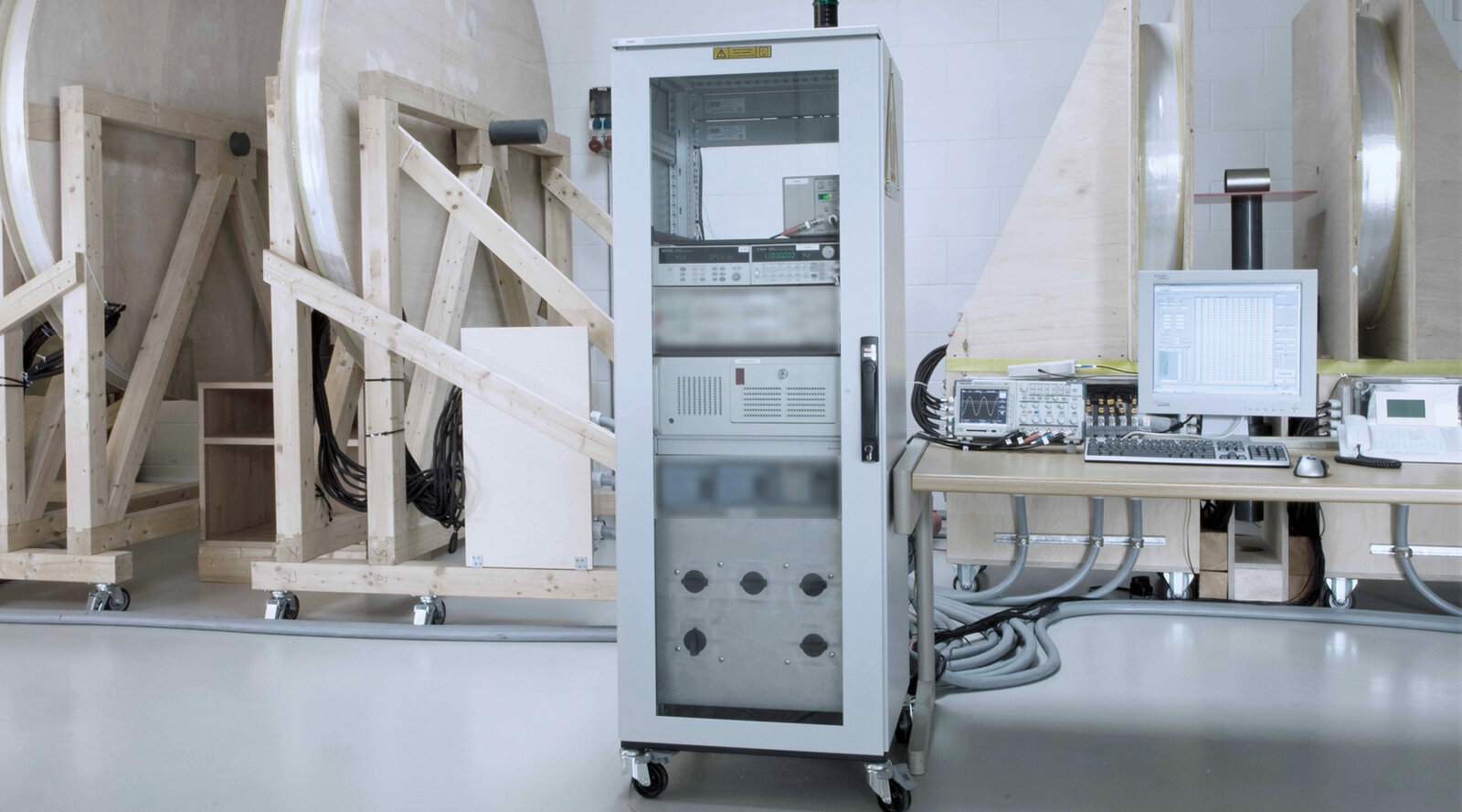

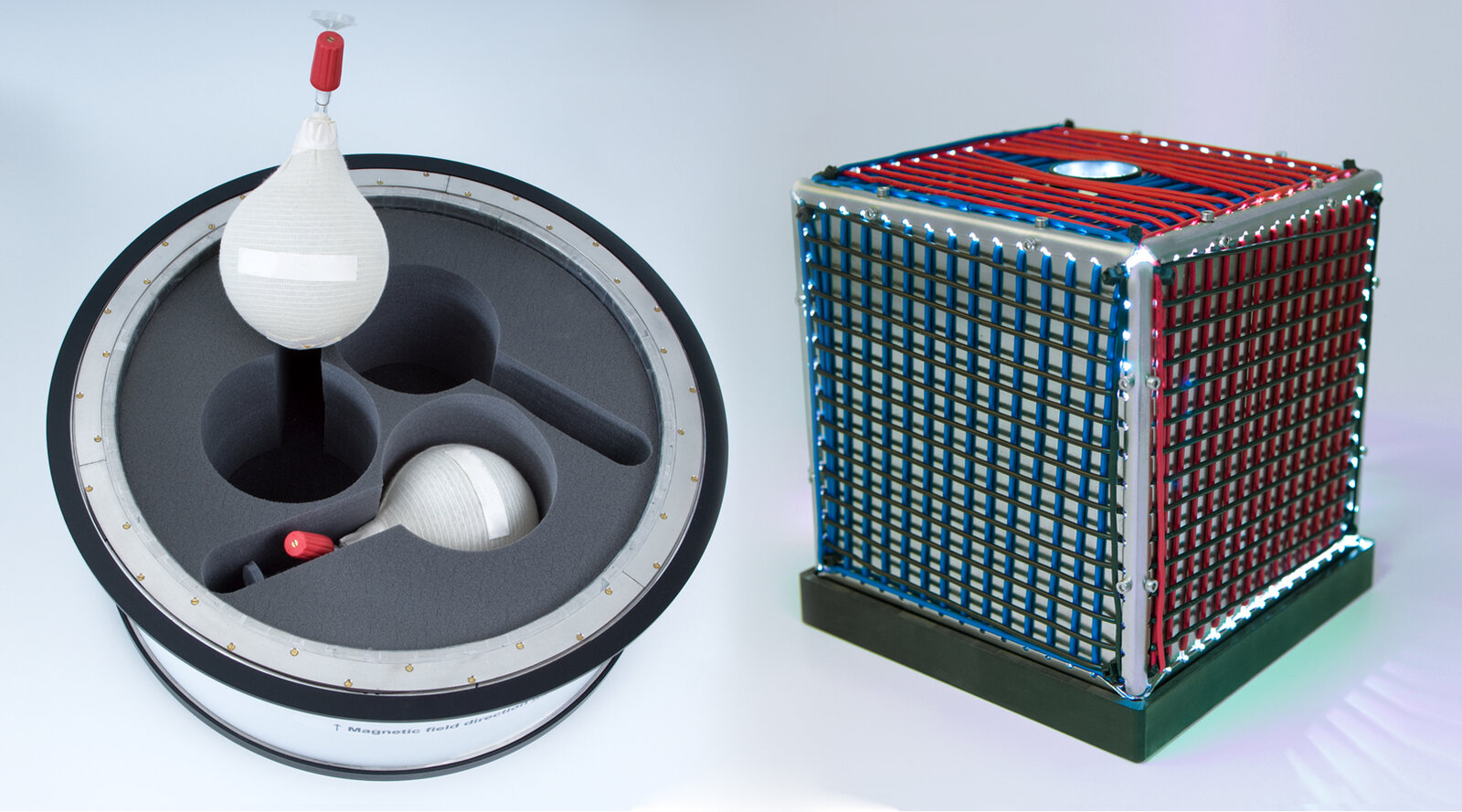

We stock all relevant alloys from 80 % NiFe to 50 % CoFe and we are familiar with alloy specific machining methods, from simple pre-cut parts to sophisticated composite systems. Computer-assisted testing and verification of the shielding factor is possible in Helmholtz systems featuring diameters up to 2 meters.

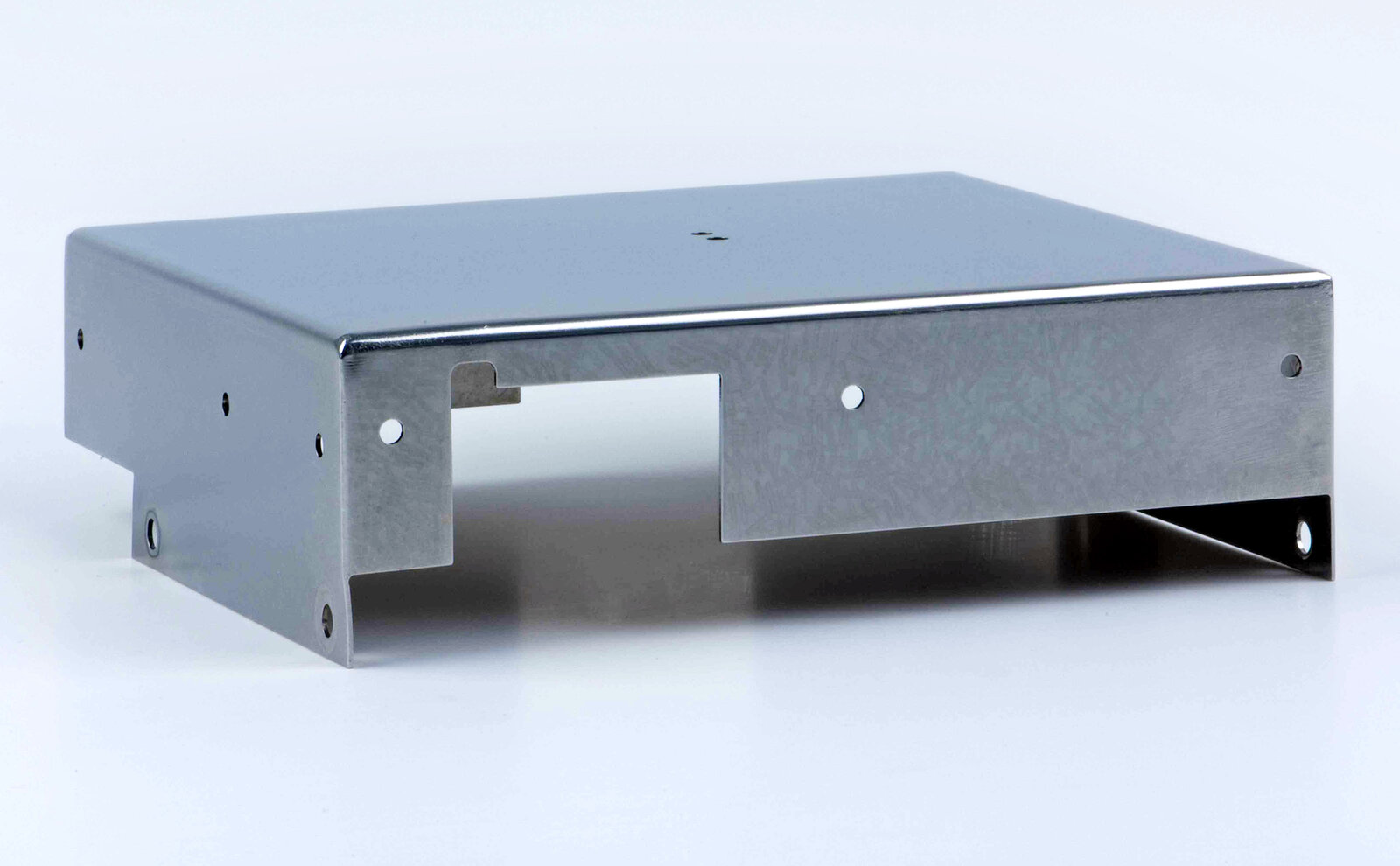

Magnetic shielding foils, tubes and cans

Different problems demand different solutions – and this also applies to magnetic shielding.

Simple shielding can be carried out using standardised or near-standard products. Foil made from the materials VITROVAC® 6025 X or MUMETALL® is particularly suitable for initial experiments. As a rule, however, production of shielding will be preceded by a planning and design phase.

Shielding forms

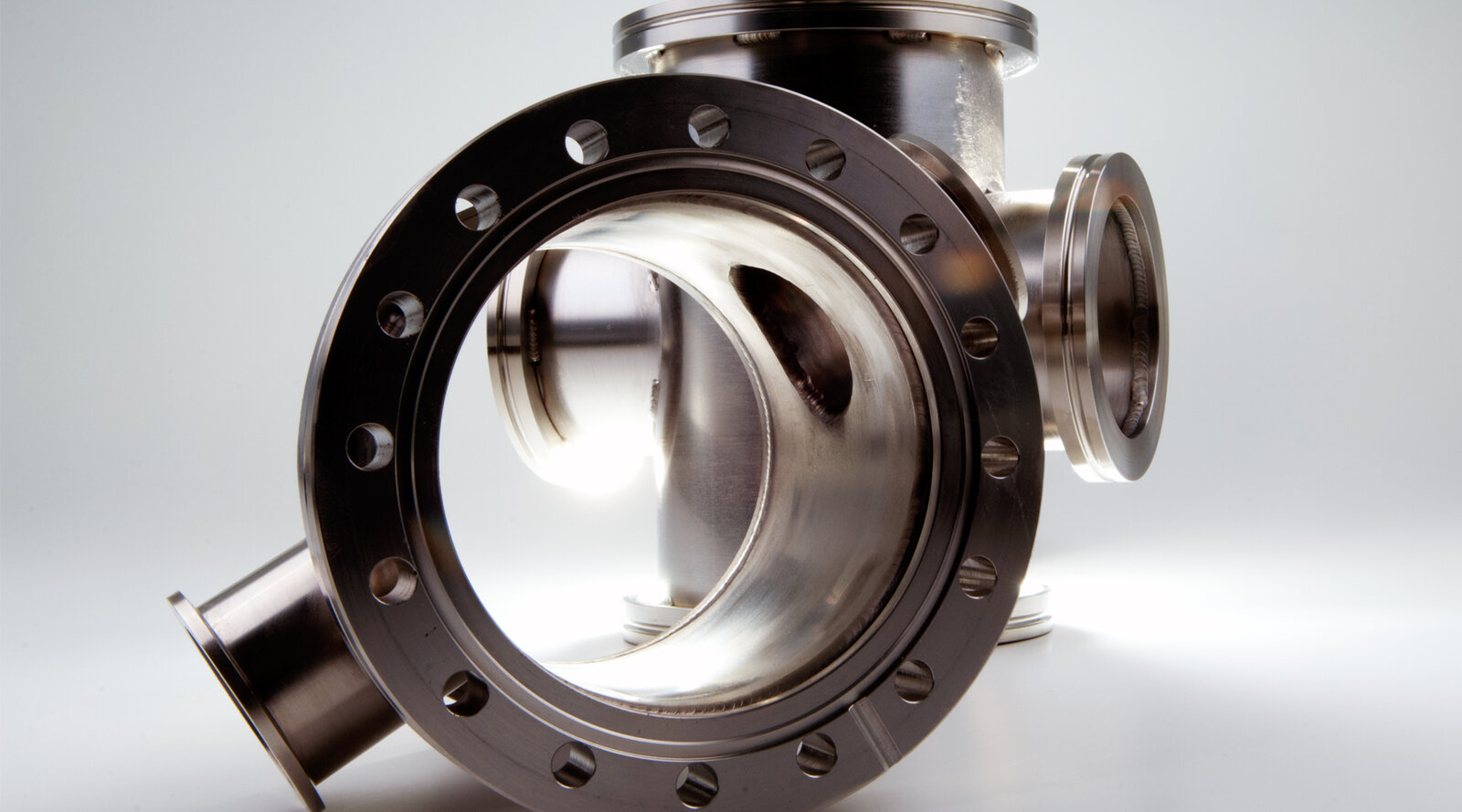

More „sophisticated“ profiles are produced by metal machining, forming, welding etc. This processing requires some specific adjustments to the materials special mechanical properties. A possible influence on shape and tolerances as a consequence of the annealing treatment needs to be considered.

Especially with complex forms with many openings FEM results should be taken with some care and the shielding factor should be verified by measurements.

Criteria for a suitable shielding solution

Among the determining criteria for a suitable shielding solution are:

- Magnetic field force and field flux

- Magnetic field frequency

- Spatial limitationsEnvironmental conditions such as temperature, humidity etc.

- Visual impression

- Cost

VACOSHIELD shielded rooms from Vacuumschmelze GmbH & Co. KG

made of Mumetal and Mumetal composite with high shielding factors also for constant fields are a speciality of Vacuumschmelze GmbH & Co. KG. Information can be found in the flyer below. If you have any questions, please contact Vacuumschmelze directly or contact us.

Theoretical basis

The shielding effect of electrically conductive materials is based on field reflection caused by induced eddy currents in the material. However, this mechanism does not work at low frequencies, thus non-magnetic materials like copper or aluminium are almost ineffective against low-frequency or static magnetic fields.

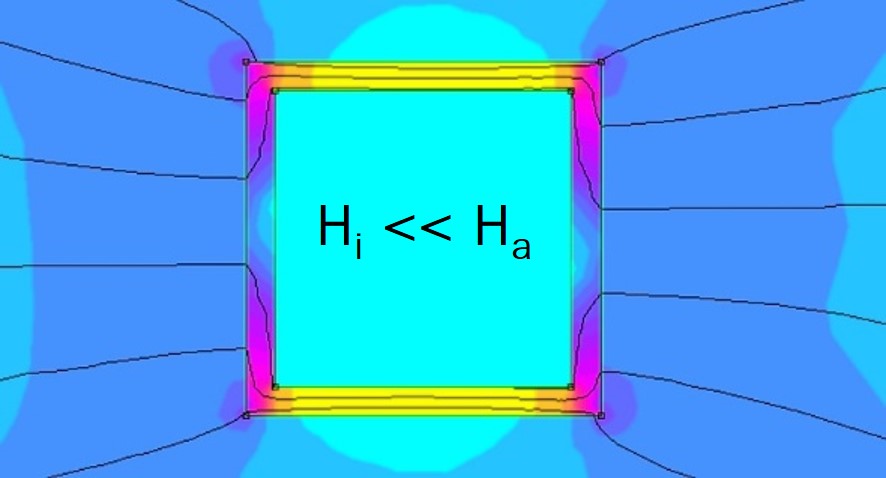

To effectively shield static or low-frequency magnetic fields, ferro-magnetic materials are used. Compared to air, they have a magnetic conductivity (permeability) which is several orders of magnitude higher. The field is redirected through the magnetic material and the field strength in the inner of a magnetically shielded space is significantly reduced.

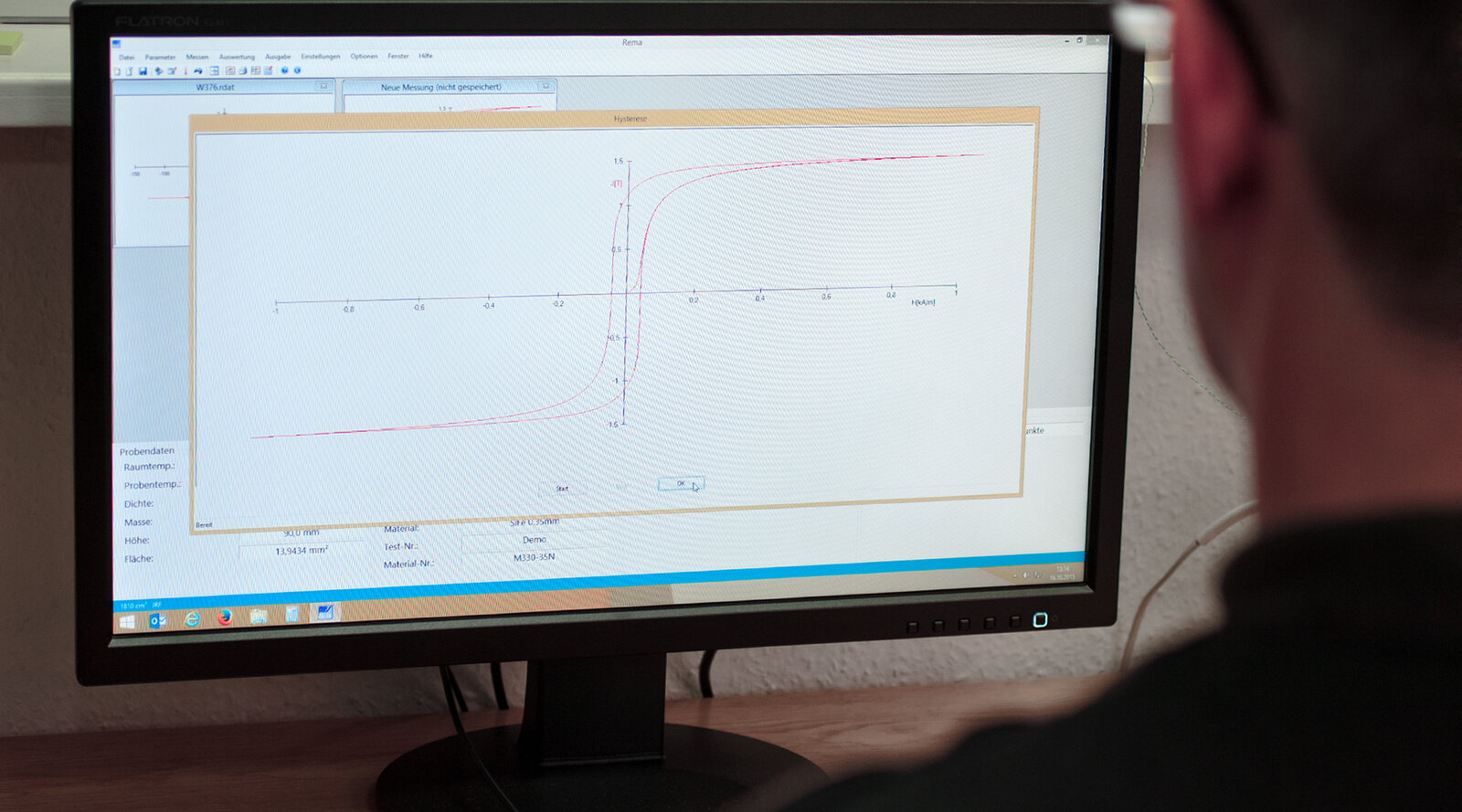

The shielding factor S is the ratio between the outer field Ba and the inner field Bi in a shielded space. For a closed cylindrical shielding in a transverse field, the following formula can be used as an approximation:

S = µ * d / D

where µ = relative permeability, d = wall thickness and D = diameter of the cylinder.

Real shielding problems can rarely be solved by analytic methods. Also FEM simulations often yield significant deviations from reality.

Downloads

-

-

HOMIE (magnetically shielded variable and homogenious magnetic field system) Product Information 10 MB

-