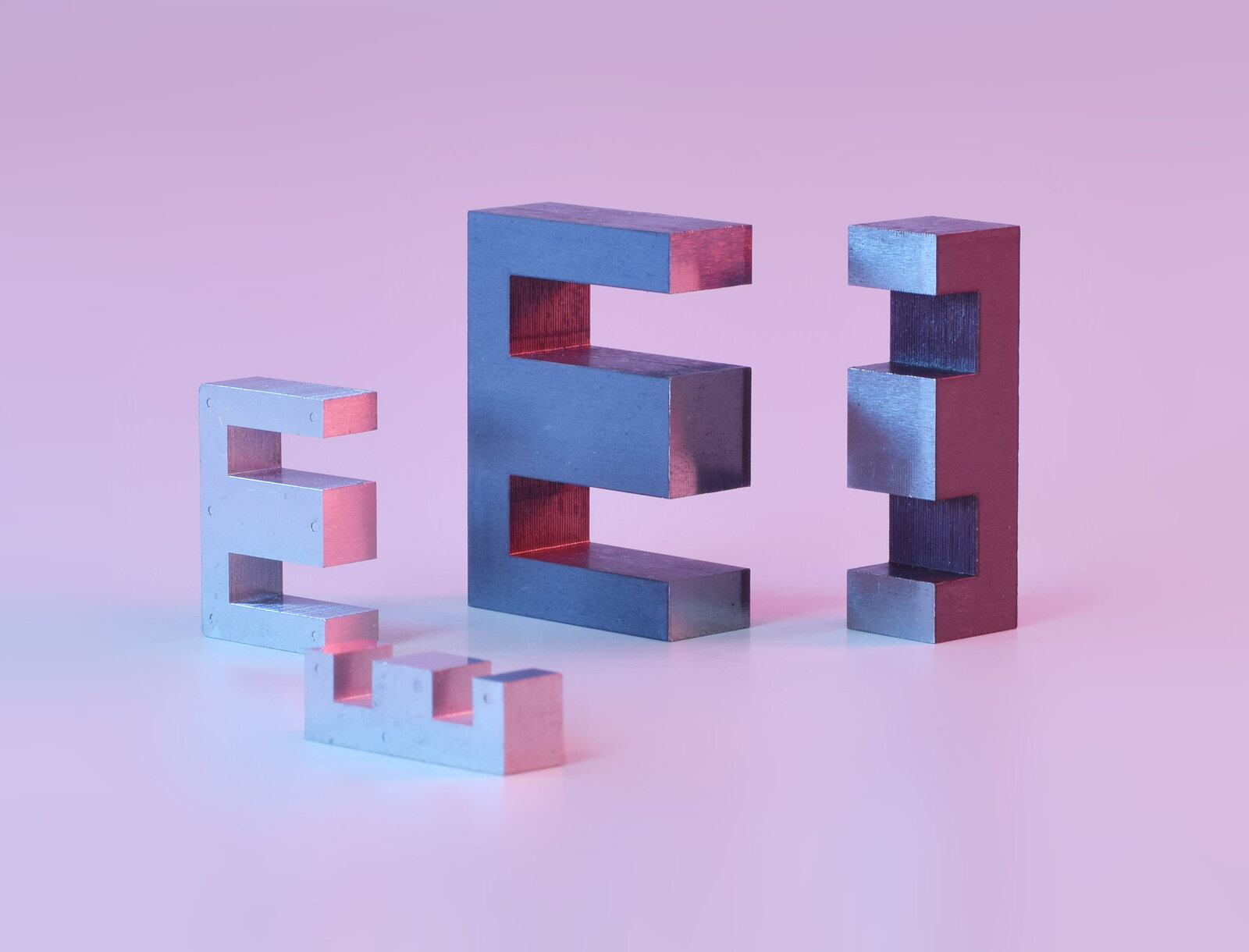

Forms of Supply Core Packages

Core packages are produced by stacking single laminations and finishing the package by impregnation, welding or mechanical interlocking. This allows, combined with standard coil-formers, a fast and cost-effective production and assembly. Compared with alternated stacked individual laminations, core packages show lower effective permeabilities even when they are face grinded. They are however especially suitable for applications which need tolerated AL values, like e.g. chokes with pre-magnetization.

Additionally SEKELS GmbH is offering customer-specific laminations and packages, from prototyping to high quantity production.

Standard Types

Standard core packages are described in DIN EN 61021. The EK types, stacked from EE laminations, are optimized for an effective build-up. They feature a square ground area, and a square cross-section of the middle leg. The ratio of the total core cross section to the winding space is 1:1,55. All EK types are geometrically similar.