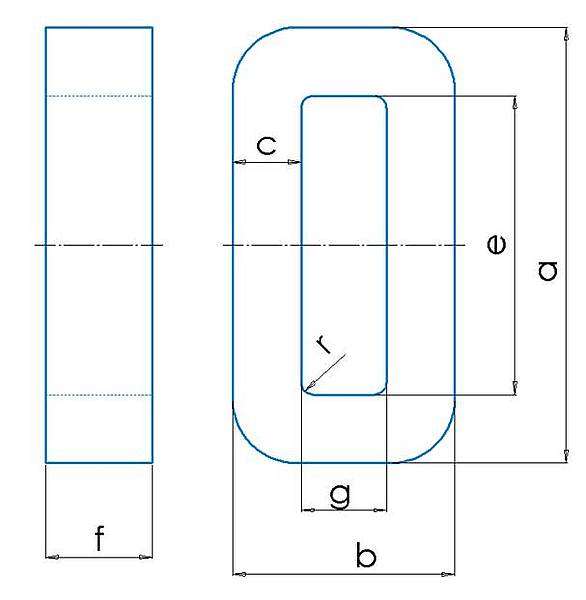

Standard Sizes of Amorphous C-Cores

| Type | Outer lenght | Outer width | Core height | Window lenght | Window width | Core build | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| a [mm] | ± | b [mm] | ± | f [mm] | ± | e [mm] | g [mm] | c [mm] | ± | |

| AMCC 20 | 72 | 2,0 | 35 | 1,0 | 30 | 0,5 | 50 | 13 | 11 | 0,8 |

| AMCC 32 | 82 | 2,0 | 41 | 1,0 | 30 | 0,5 | 56 | 15 | 13 | 0,8 |

| AMCC 50 | 102 | 3,0 | 52 | 1,0 | 25 | 0,5 | 70 | 20 | 16 | 1,0 |

| AMCC 80 | 102 | 3,0 | 52 | 1,0 | 40 | 1,0 | 70 | 20 | 16 | 1,0 |

| AMCC 100 | 102 | 3,0 | 52 | 1,0 | 45 | 1,0 | 70 | 20 | 16 | 1,0 |

| AMCC 125 | 121 | 3,0 | 63 | 1,0 | 35 | 1,0 | 83 | 25 | 19 | 1,0 |

| SU 75b | 125 | +3,5 -2,0 | 72,4 | +3,0 -2,0 | 40 | 1,0 | 78 | 25 | 23,7 | 1,0 |

The amorphous strip is fairly brittle after annealing. The handling of the cores requires stringent safety procedures (eye protection) that are caused by chipping splinters. Damaged inner and outer core layers are not possible to avoid during the manufacturing process and no quality criteria. Magnetic properties are not influenced by broken outer and inner layers.

|

type |

lFe |

AFe |

mFe |

Acu, 50% |

lCu |

effective surface O |

|---|---|---|---|---|---|---|

|

|

[cm] |

[cm²] |

[g] |

[cm²] |

[cm] |

[cm²] |

|

AMCC 20 |

17,5 |

2,7 |

337 |

3,3 |

13,4 |

ca. 172 |

|

AMCC 32 |

20,0 |

3,2 |

454 |

4,2 |

14,6 |

ca. 216 |

|

AMCC 50 |

24,9 |

3,3 |

586 |

7,0 |

16,2 |

ca. 303 |

|

AMCC 80 |

25,4 |

5,2 |

938 |

7,0 |

19,2 |

ca. 356 |

|

AMCC 100 |

25,0 |

5,9 |

1055 |

7,0 |

20,2 |

ca. 373 |

|

AMCC 125 |

30,2 |

5,5 |

1166 |

10,4 |

20,8 |

ca. 464 |

|

SU 75b |

31,0 |

7,7 |

1764 |

9,8 |

22,7 |

ca. 533 |

For more size please see our brochure.