Amorphous Metals (VITROVAC®)

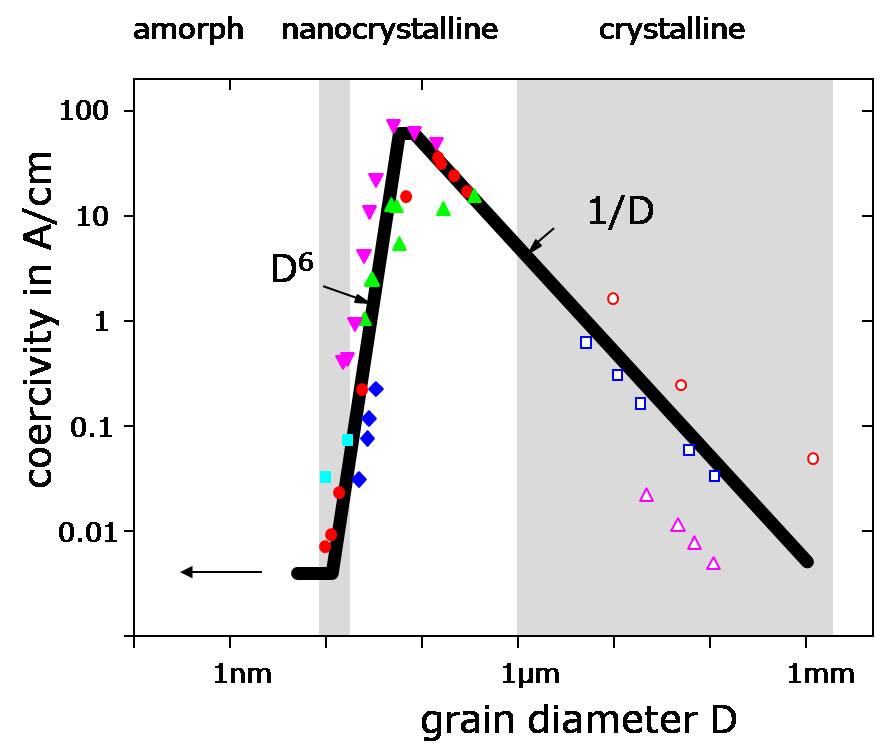

Amorphous Metals (VITROVAC®) are produced with a special rapid solidification technology with cooling rates of about one Million Kelvin per second directly in one step in form of thin tapes (typical thickness about 0,02 mm). As magnetic cores in inductive components they have been widely replaced meanwhile by nanocrystalline alloys, which are produced the same way. However amorphous metals are still in use e. g. in saturable reactors, and they enable sophisticated solutions, e. g. in research applications.

Nanocrystalline alloys (VITROPERM®)

Nanocrystalline alloys (VITROPERM®) are modern soft magnetic alloys with reasonable material costs and excellent magnetic properties such as high permeabilities combined with high saturation flux density, excellent temperatur stability and favourable frequency characteristics. They are available in various standard series with different permeability levels and mechanical fixations (plastic case FIX 022, epoxy coating FIX 350).

For more Information about nanocrystalline alloys please see the document "Nanocrystalline soft magnetic cores - an interesting alternative not only for highly demanding applications".

Crystalline high-permeability NiFe alloys

Crystalline high-permeability NiFe alloys are meanwhile widely replaced by nanocrystalline alloys. They are however still available for several special applications.

Properties of alloys for Tape-wound Cores

| Alloy | Composition | µmax (50 Hz) | µi (10 kHz) | HC [A/m] | BS [T] | TCurie [°C] | Density [g/cm³] |

| ULTRAPERM® 250 | 80 % NiFe | 400000 | - | 0,3 | 0,78 | 400 | 8,7 |

| VITROPERM® 800 F | Fe nano | 150000 | - | 0,5 | 1,20 | 600 | 7,35 |

| VITROPERM® 500 F | Fe nano | - | 20000... 100000* | 0,5 | 1,20 | 600 | 7,35 |

| VITROPERM® 250 F | Fe nano | - | 4000 | 1,0 | 1,20 | 600 | 7,35 |

| VITROPERM® 500 Z | Fe nano | - | - | 0,5 | 1,20 | 600 | 7,35 |

| VITROVAC® 6025 Z | Co amorphous | - | - | 0,3 | 0,56 | 240 | 7,7 |

* Permeability levels are adjusted during the final magnetic annealing